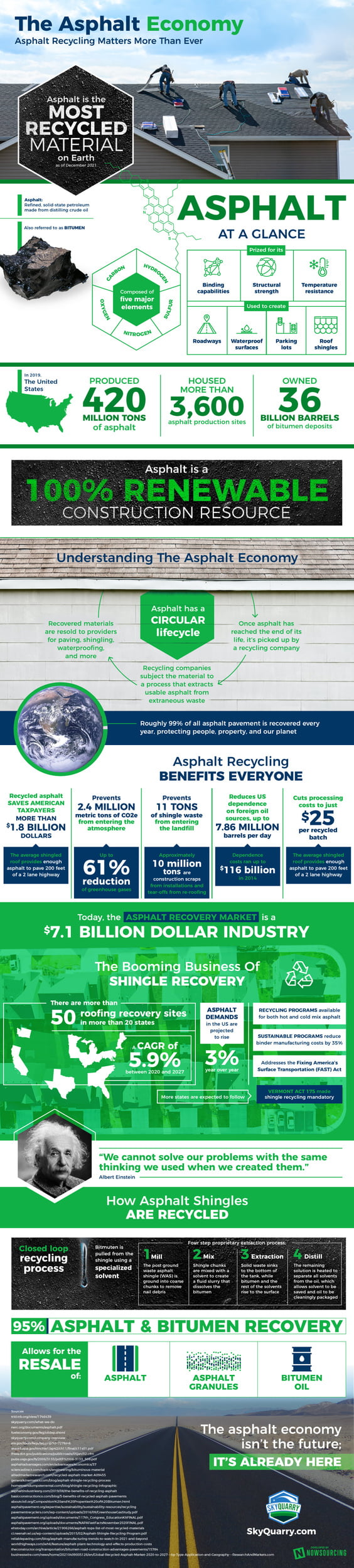

Asphalt, a petroleum-like material obtained from distilled crude oil, is a 100% renewable resource. Also called bitumen, it usually consists of elements such as hydrogen, carbon, and sulfur. Asphalt is usually used to produce roads, parking lots, and roof shingles due to its structural strength, resistance to temperature changes, and binding capabilities. The U.S. produces tons of asphalt, houses thousands of asphalt production plants, and owns billions of barrels of bitumen.

Q4 2021 hedge fund letters, conferences and more

Recycling Asphalt

The ability to recycle asphalt allows it to be reused for projects such as paving and shingling. This is done through recycling companies gathering old asphalt and extracting the usable parts from the asphalt that can no longer be used. Every year in the U.S., 99% of asphalt in the form of pavement is recovered and recycled.

Recycling asphalt can help save both the environment and money. Reusing asphalt can save U.S. citizens more than $1.8 billion as the average shingled roof results in an amount of asphalt that can be used to completely pave 200 feet of a highway with two lanes. This also removes 11 tons of shingle waste from landfills where at least 8.8 million tons of asphalt end up each year. Asphalt recycling means the U.S. does not need to depend on foreign sources to get oil as well, which significantly helps with reducing costs considering that dependence costs in 2014 reached $116 billion.

Shingle recovery has been gaining traction as a business in recent years. Programs have been produced to help with decreasing binder manufacturing costs and making hot and cold mix asphalt more available. The number of roofing recovery sites has increased in at least 20 U.S. states as the demand for asphalt is estimated to increase by 3% each year. Vermont even has a law that makes shingle recycling an obligation in the state, which is something that could possibly be made mandatory in other states as well.

Like the asphalt recycling process there are several steps to asphalt shingles recycling. The asphalt shingle waste is first crushed into loose chunks to remove any unnecessary debris before being mixed with a solvent that causes the bitumen and the rest of the solvents to separate from the solid waste and oil. This allows the solvent to be saved while the oil can be packaged.

The recycled asphalt market is a continuously growing industry that benefits everyone.

Infographic Source: InvestSkyQuarry.com