The evolving social and digital media platforms and highly innovative and relevant payment capabilities are causing seismic changes in consumer behavior and creating equally disruptive opportunities for business. – Howard Schultz

As regular readers of the Absolute Return Letter will know, we run a list of structural mega-trends which will form the world as we know it for many years to come – and that list drives our investment strategy. A couple of weeks ago, we added Disruption to that list, taking the total number from six to seven.

Here’s The Case For An Upside Risk In The Global Economy

Now, what is disruption? Let me offer one definition, although there are many. Disrupters originate in low-end or new-market footholds. Disruption doesn’t happen overnight but is a process and, because disruption takes time, incumbents frequently overlook disrupters until it is too late. (Source: “What Is Disruptive Innovation?”, Harvard Business Review, December 2015).

The mantra “disrupt or be disrupted” can lead to erroneous business decisions. Incumbents do need to respond to disruption, but they should not overreact by dismantling a profitable business.

Some disruptive businesses succeed whereas others don’t. It is a misconception that entrants are disruptive by virtue of their success. Success is not built into the definition of disruption. Now, that is about how Harvard Business Review defines disruption, but there is more to the story than that.

The number of years to fully disrupt incumbents is falling precipitously (Exhibit 1). I remember the days of proudly showing my new Eastman Kodak to anybody who cared. I had just received my first ever monthly salary, most of which was spent on this fancy camera. Those were happy days, but suddenly disrupters took the fun away. My Kodak was no longer smart. It was hopelessly outdated, and I couldn’t convert to a digital camera quickly enough. Of course, digital cameras have since been disrupted by smartphones, but that is another story.

Kodak may have been one of the first victims of disruption, but is far from the only one. Think Netflix and what that company has done to Blockbuster, what iPhone has done to Blackberry, or the damage Amazon has done to retailers all over the world. And, now, Amazon has decided to enter the retail industry after years of disrupting other retailers.

Even worse (for the incumbents), Amazon is far from done yet. It has just entered the banking industry (engaging itself in corporate lending), and it has just acquired the streaming rights for 10 Thursday night NFL games. If the live sports model works for Amazon, it is only a question of time before it will outmuscle European broadcasters for the right to show live football (soccer) in Europe. I am not sure I want to be a Sky or BT shareholder when that happens.

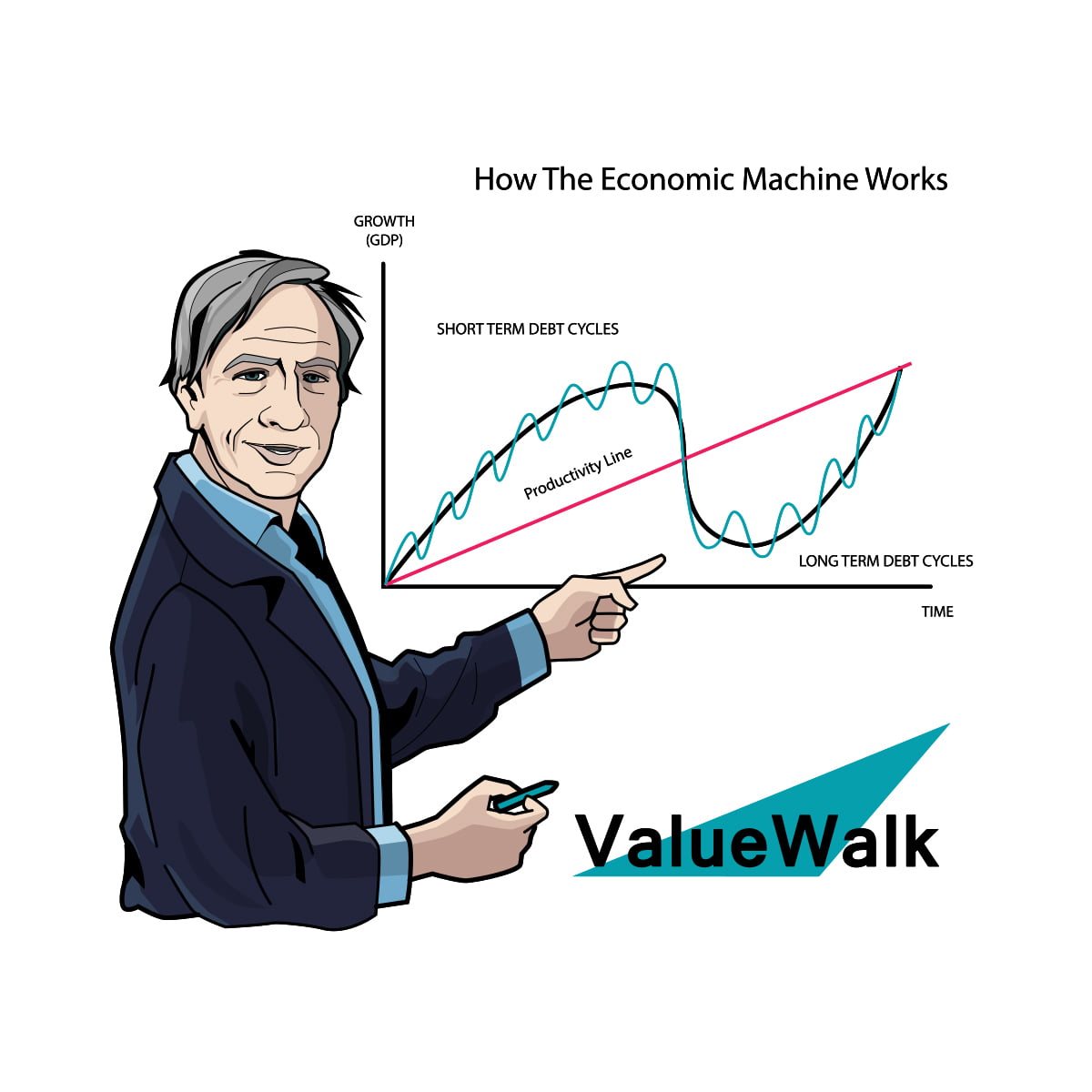

Exhibit 1: The number of years to disrupt incumbent businesses.

Source: Arrowgrass Capital Partners LLP, May 2017.

Advanced robotics

In the following, I shall focus on only one of many disruptive innovations – advanced robotics. There are admittedly many other innovations I could write about, but I am sure you will appreciate not holding a 300-page long document in your hands right now.

Some disruptive innovations, such as renewable energy, get more media attention than can be justified from an impact point-of-view (Exhibit 2), but advanced robotics is not one of those. Robots will almost certainly have a massive impact on productivity, on economic growth, and therefore on life in general.

Source: “Disruptive technologies: Advances that will transform life, business, and the global economy”. McKinsey Global Institute, May 2013.

The market for advanced robotics is in reality four different markets – personal, commercial, industrial and military. The industrial segment is the largest, but the personal segment is expected to grow the fastest – 17-18% annually for many years to come (Exhibit 3).

Source: “Robot Revolution”. BofAML, November 2015.

The key driver - the cost advantage

The industry that has been penetrated the most by robots so far is the automotive industry, and it is not difficult to understand why that is. At the time of BofAML’s research into the topic (November 2015), a spot-welder working in the US automotive industry was paid about $25 per hour. A spot-welding robot could do the same job for about $8 per hour (all in), and the difference will only get bigger in the years to come (Exhibit 4).

*The cost is for a US spot-welding robot.

Source: “Robot Revolution”. BofAML, November 2015.

Other industries are not yet where the automotive industry is, but it is only a question of time. Take the electrical equipment industry, where the cost advantage is about to swing away from manual labour towards advanced robotics (Exhibit 5).

**An example of a generic robotics system is ABB’s IRB 2400

Source: “Robot Revolution”. BofAML, November 2015.

The furniture industry is further back in that chain. The cost disadvantage of using robots is still significant, but robots will almost certainly catch up eventually (Exhibit 6).

***Includes other wood products

Source: “Robot Revolution”. BofAML, November 2015.

The robots will take over

The world will change dramatically as a result of advanced robotics, but is it for the better or worse? BofAML’s research analysts argued in their report that robots will take over nearly 50% of all manufacturing jobs and shave $9 trillion off labour costs within a decade. I don’t know enough about robots to argue for or against those numbers and the suggested timeline of it all, but the trend is clear, and the driver is first mover advantage. Those countries that don’t embrace the new technology will simply be left behind, such are the advantages (Exhibit 7).

Source: “Robot Revolution”. BofAML, November 2015.

Developed economies have a massive advantage over China in this respect. China, because of the sheer number of people, cannot allow robots to replace hundreds of millions of workers. There are simply too many mouths to feed every day.

The old world has exactly the opposite problem. A shrinking workforce will force robots to be installed if we want to keep industry alive, partly because we won’t have enough people to fill the manufacturing floors, and partly because those who are left will be too expensive to do the job. The best line of defence against Chinese competition is therefore likely to be more automation.

A myth to be debunkedI often run into the argument that robots have already cost loads of manufacturing jobs, but nothing could be further from the truth. Take another look at Exhibit 7. Which European country has installed most robots so far? The answer is Germany. Which country has installed the fewest? As you can see, the answer is the UK.

Now, switch your attention to Exhibit 8. In which country have the fewest manufacturing jobs been lost in recent years? The answer is Germany. And in which country have the most manufacturing jobs been lost? Surprise, surprise – the answer is the UK.

As you can see from Exhibit 8, there is virtually no correlation between the use of robots and employment in the manufacturing industry. Robots don’t cost jobs (at least not at a grand scale) – poor competitiveness does. While the average Brit argues that Brexit will lead to improved competitiveness as far as the UK is concerned, Brexit is not at all the answer to Britain’s poor competitiveness. Low penetration of advanced robotics is.

Source: “Don’t blame the robots for lost manufacturing jobs”, Brookings Institute, April 2015.

The impact on inflation - the two extremes

Let’s revisit BofAML’s projection that 50% of all manufacturing jobs will be lost between now and 2025. That could potentially raise unemployment levels quite dramatically and, by implication, increase the economic slack, which would almost certainly put further downward pressure on inflation.

As far as labour market projections are concerned, the two extreme cases in the Western world are the US and Germany. (In some respects, Italy is even more extreme than Germany). Whereas the US workforce will continue to grow - albeit modestly – the German workforce will shrink substantially between now and 2050.

In the US, 15.4 million people are employed in manufacturing (Source: OECD). Consequently, if BofAML is about right, 7.7 million workers should lose their jobs over the next 10 years. That’s a shade under 5% of the US workforce.

On top of that, per United Nations data, the US workforce should grow by about 0.25% annually between now and 2050. Consequently, it may prove more difficult than it normally would for new job market entrants to land their first job.

Now, compare those stats to those of Germany. In Germany, 7.9 million workers are employed in manufacturing, so 3.95 million are at risk of losing their jobs if BofAML projections are correct but, because of ageing, the German workforce will, unlike the US workforce, shrink considerably in the years to come.

The German civilian workforce is made up by 42 million people (Note: latest available data is from 2015), but it is expected to shrink by 0.8% annually between now and 2050 (according to UN data). In other words, by 2050, the German workforce should be down to about 31.7 million workers – a drop of more than 10 million workers!

Although the fall is back-end loaded (most will drop out of the workforce between 2030 and 2050), for the case of simplicity, let’s assume it is a straight line, which would imply that the German workforce will have fallen by 3¼ million people by 2025 – 10 years after BofAML made their projection that almost 4 million Germans are at risk of losing their jobs to robots between 2015 and 2025.

The conclusion is straightforward. Whereas automation could put severe pressure on the US manufacturing workforce, a shrinking German workforce (caused by ageing) will effectively deal with that challenge.

The outlook for the UK

The UK languishes somewhere in between those two extremes. The UK civilian workforce was made up by 32.6 million people in 2015 and is estimated to grow by 0.1% annually between now and 2050, implying that the UK workforce should have grown by 1.2 million workers by then.

Now, if you go back to Exhibit 7 for a moment, you will see that the UK doesn’t do particularly well in the automation league tables – only China is inferior to the UK. One could argue that, with a (modestly) growing workforce, the UK doesn’t face the same need to automate that Germany does, and that is indeed correct if the sole purpose is to keep manufacturing jobs alive. However, if you want to compete internationally, you don’t really have a choice but to ramp up automation.

Concluding remarks

I can only conclude that the inflationary implications of advanced robotics are likely to vary quite meaningfully, subject to where on the demographic curve the country in question is. Obviously, if history repeats itself and no manufacturing jobs are lost as a result of advances in technology, my conclusion would be different, but let’s assume advanced robotics will do more damage to employment than any other new technology has ever done before.

In that case, the projected decline in the German workforce caused by ageing will largely offset the loss of jobs caused by advanced robotics; there may even be a shortage of workers in Germany at some stage.

Meanwhile, in the US, the outlook is very different. Because the workforce will continue to grow, the economic slack will worsen as more and more robots are introduced, and that will most likely prove disinflationary – maybe even deflationary. In other words, my short-term concerns about tightness in US labour markets and the effect that is likely to have on inflation and interest rates could, over time, change 180 degrees.

And it is not only wage inflation that advanced robotics is likely to affect. The researchers from BofAML reckon that, whilst robots have on average become 27% cheaper over the last 10 years, they will fall a further 20% or more over the next 10 years. This would allow producer prices to fall quite substantially.

So, yes, robots are indeed disruptive, but they could very well prove the saving grace for a number of otherwise doomed (mostly European) economies. How quickly it will all happen remains to be seen, but it is beyond doubt that automation will be a massive theme in the years to come.

A couple of comments re the implementation of disruption in your investment strategy. Firstly, the fact that the disrupter is not always the winner makes it a tad more complicated. Secondly, companies often start to disrupt long before they list on a stock exchange. I am fully aware that investors continue to make zillions of dollars on Amazon, but Amazon is indeed the exception to the rule.

Consequently, I am in favour of the portfolio approach to disruption (venture capital or private equity being the most obvious choices), although I can think of one or two exceptions to that rule; however, the lawyers won’t allow me to mention anything specific in this letter (it is deemed to be advertising of non-regulated investment schemes, which is not allowed), so I should probably stop now.

However, before I do so, one last word – and a word of caution that is. From everything I have read on the topic, the view seems to be that automation will mostly affect manufacturing, but that is indeed a misconception. Take a simple example – education. A single professor can now, through digital technology, teach a course to millions of students all over the world.

Article by Niels Clemen Jensen, Absolute Return Partners