The environmental impact of vinyl on the planet is one of the music industry’s (many) dirty little secrets. Norman Records have been investigating, and found that last year alone over 4 million new vinyl records were purchased, and considering the average LP weighs about 135g, that means that over 550 tonnes of our favourite black plastic – with all its associated energy and environmental costs entered into the market at a time when we should all be thinking about reducing our carbon (and plastic) footprints. So, streaming to the rescue of the environmentally friendly, right? Maybe not.

[REITs]Q1 hedge fund letters, conference, scoops etc

The vinyl vs streaming comparison isn’t easy, and there are conflicting views and statistics. Any given record is the product of countless processes, all with their own ecological costs. Streaming, however, isn’t the magical solution some believe it to be either. Cloud computing is environmentally dangerous too. YouTube, Spotify, Apple Music, SoundCloud – all depend on a network of energy-intensive server farms, mammoth fibre-optic cables laid on precious ocean beds, rare metals destructively mined for computers, routers, iPhones, etc. One study claims that streaming an album over the internet 25+ times may actually use more energy than the manufacturing of a physical album on CD.

In other words, whilst a physical album has a higher upfront cost of production it may have a lower footprint over time, requiring only enough electrical energy for physically spinning the inert record (or CD) and providing its amplification. Streaming reduces the upfront production but makes increased demands over time, with storage, retrieval and global transmission of computer files required for each and every play.

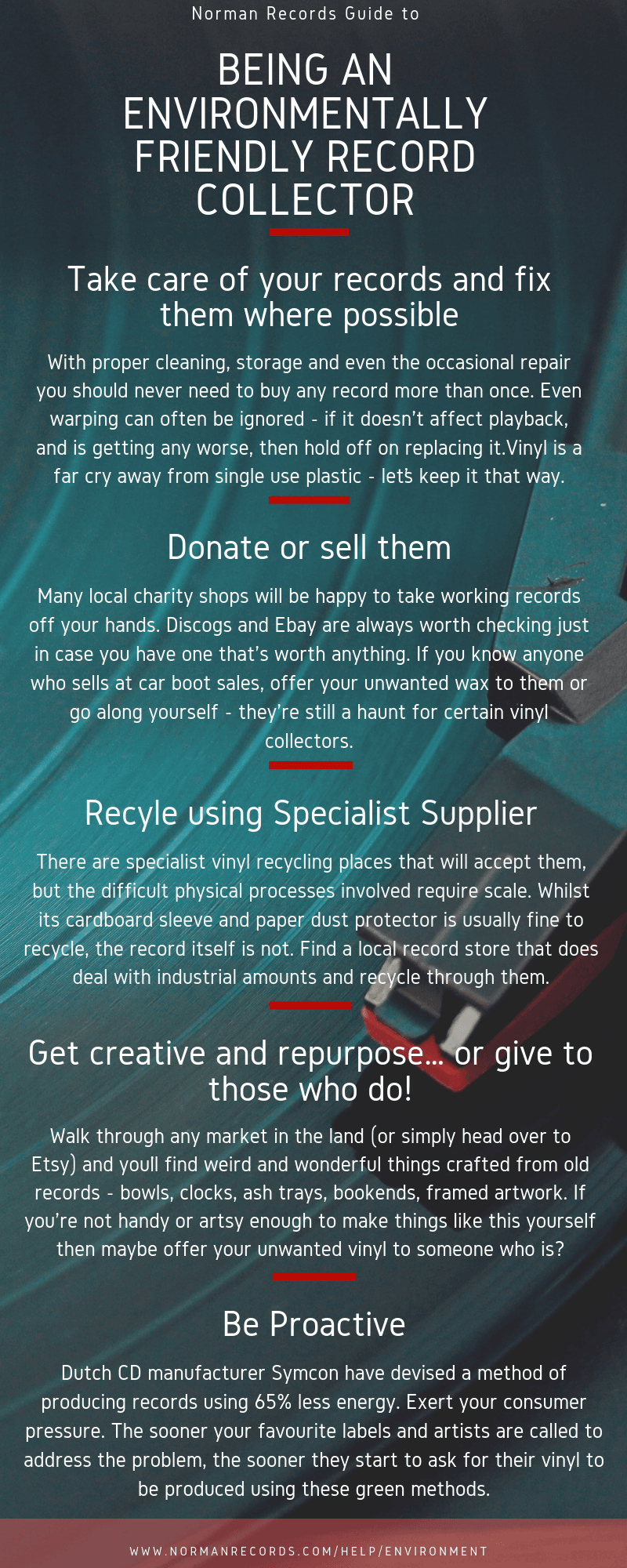

Environmentally Friendly Tips And The future of vinyl manufacturing

For most of the past century creating a new record has involved casting an aluminum platter before heating the PVC in a press to form the vinyl disc. First devised in the 50s, this method of production not only consumes vast amounts of energy but the continual force used by this process causes wear on the stampers, meaning they have to be replaced frequently.

Step forward Dutch CD manufacturer Symcon, who have devised a method in which a pre-heated plastic mixture is injected into the mould where it cools and sets. As no pressure is used on the stampers, they last considerably longer. It may not quite live up to their promise of “an environmentally friendly alternative production process for vinyl records” but, overall, this method is estimated to use 65% less energy and has received grants from the European Union to help make the technology more readily available.

Awareness of it matters. The sooner your favourite labels and artists start to ask for their vinyl to be produced using these greener technologies, the sooner we can all start to feel a little less guilty about our vinyl habit.