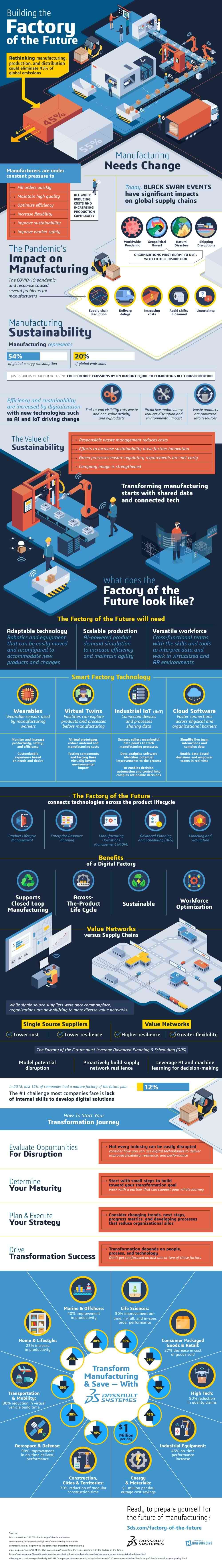

With disruption, innovation, and global connectivity working together, the way manufacturers deliver in today’s experience is being constantly reshaped. Competition, unexpected events, and consumer demand all put relentless pressure on manufacturers. For them to deliver in the best way possible, a world-class business platform can help digitally transform operations and prepare for the brave new world.

Q3 2021 hedge fund letters, conferences and more

Planning The Factory Of The Future

The first thing to consider in planning the factory of the future is resource usage. Define and simulate the plant’s layout, flow, assets, and resources as they are needed to produce products efficiently and safely. With 3D virtual experience technology, it is possible to rapidly validate normal production change requests or, in the case of disruptive events, pivot to alternative products.

Once resources are planned out, the manufacturing process needs to be defined and validated. Process plans and work instructions must be clear cut and capable of meeting production goals. Again, digital visualization can accelerate time to production in almost any scenario. With the cloud at a business’s disposal, such planning can happen from any location. Businesses can transform global production operations like never before, all while maintaining operational integrity to meet dynamic demand circumstances.

Handling Black swan Events

With matters inside the factory settled, affairs concerning supply chain planning and optimization should be tackled next. Right now, supply chains are a touchy subject with manufacturers and retailers alike. Black swan events like COVID-19 and natural disasters are dealing significant damage to global supply chains. Delivery delays, increased costs, and general uncertainty have all added stress to manufacturers across the globe. One way in which a digital business platform can make a stressful situation better is by giving businesses the ability to model, simulate, and optimize alternative supply and production plans to minimize disruptions.

Beyond making a factory better able to meet business demands, a reimagining of manufacturing, production, and distribution could have dramatic effects on climate change. Making changes to those 3 areas could eliminate 45% of global emissions. Manufacturing alone makes up 20% of the total. Were only 5 areas of manufacturing to change their ways, emissions could fall by the same amount as they would were all transportation eliminated. All this to say there is potential for great change here. Businesses that wish to operate in the future need a livable planet on which to do so. Efficiency and sustainability can reduce waste and costs in one. Soon, sustainable factories will be commonly seen everywhere.

Infographic Source: Dassault Systemes