Intel Corporation (NASDAQ:INTC) is implementing IoT (Internet of Things) technology in their Malaysian factory to save about $9 million.

The Internet of Things is said to offer lots of possibilities that bring everything from thermostats to cars online.

Intel’s exciting new possibilities

Industrial applications are a big part of the future. All combined with big data analytics, smarter plants can help contribute to big savings.

Manufacturers will still have to see solid evidence demonstrating IoT’s benefits before they actually get on board with the program.

Philip Cronin (sales director for Intel Asia-Pacific) offered, “We’ll have to provide proof points for a period of time to demonstrate the value and effectiveness of the capabilities,”

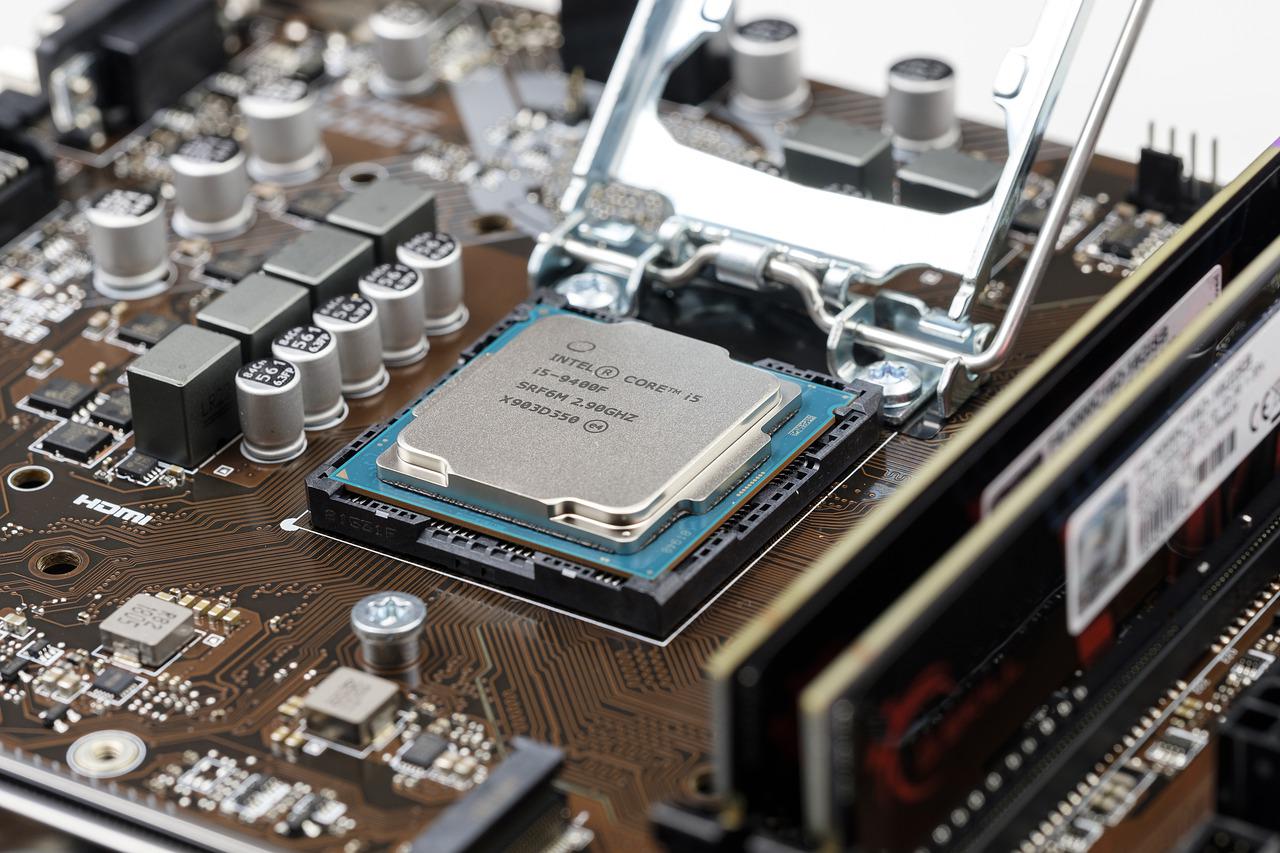

An example of IoT technologies

An example of one proof point could be a collective pilot project utilizing IoT to save money at one Malaysian plant.

CPU-based tester models in semiconductor manufacturing line were redesigned with sensors.

The data is then sent to Mitsubishi Electric C Controller gateway devices all powered by Intel Atom chips. Upon filtering, data was processed by Revolution Analytics software.

Cronin added, “This is a whole new environment for a lot of people. There’s no better place to talk about it than the fact that we did it for ourselves.

We think predictive maintenance will be one of the bigger plays because it lends itself to IoT easily.

If I have a thousand machines at a motor car plant and I can figure out which ones are running too far, too high, too soon then I start to get into predictive maintenance and the resultant savings.”

Putting the data into practice helped decrease the number of component failures and increased the productivity or equipment uptime.

Mitsubishi Electric even thinks this approach can significantly reduce energy costs within manufacturing facilities.

Applications for IoT could get a start in some areas like air conditioning, heating, and ventilation. Equipping HVAC machines with low-costs sensors and communication devices could help predict when the machines will need service.